Soldering iron heating element wiring diagram Idea

Home » Trending » Soldering iron heating element wiring diagram Idea

Your Soldering iron heating element wiring diagram images are ready in this website. Soldering iron heating element wiring diagram are a topic that is being searched for and liked by netizens now. You can Get the Soldering iron heating element wiring diagram files here. Find and Download all free vectors.

If you’re searching for soldering iron heating element wiring diagram images information related to the soldering iron heating element wiring diagram keyword, you have visit the ideal blog. Our website frequently provides you with hints for downloading the maximum quality video and picture content, please kindly search and find more informative video articles and graphics that match your interests.

Soldering Iron Heating Element Wiring Diagram. When using the soldering iron continuously, be sure to loosen the tip and remove all oxides at least once a week. When the temperature stabilizes, remove the cal pot Listed model only (2 each ) 3 ec232 handle assembly 13 n/a soldenoid / transducer assembly 4 ds103 collector tube w/gaskets 14 n/a transformer 5 ds204 filter for desoldering head 15 ph120iesd soldering iron stand (not shown) Solder one of the two red wires from the heating element to the red wire from the cord on the pcb, and then.

heater How to amplify a thermocouple that shares a wire From electronics.stackexchange.com

heater How to amplify a thermocouple that shares a wire From electronics.stackexchange.com

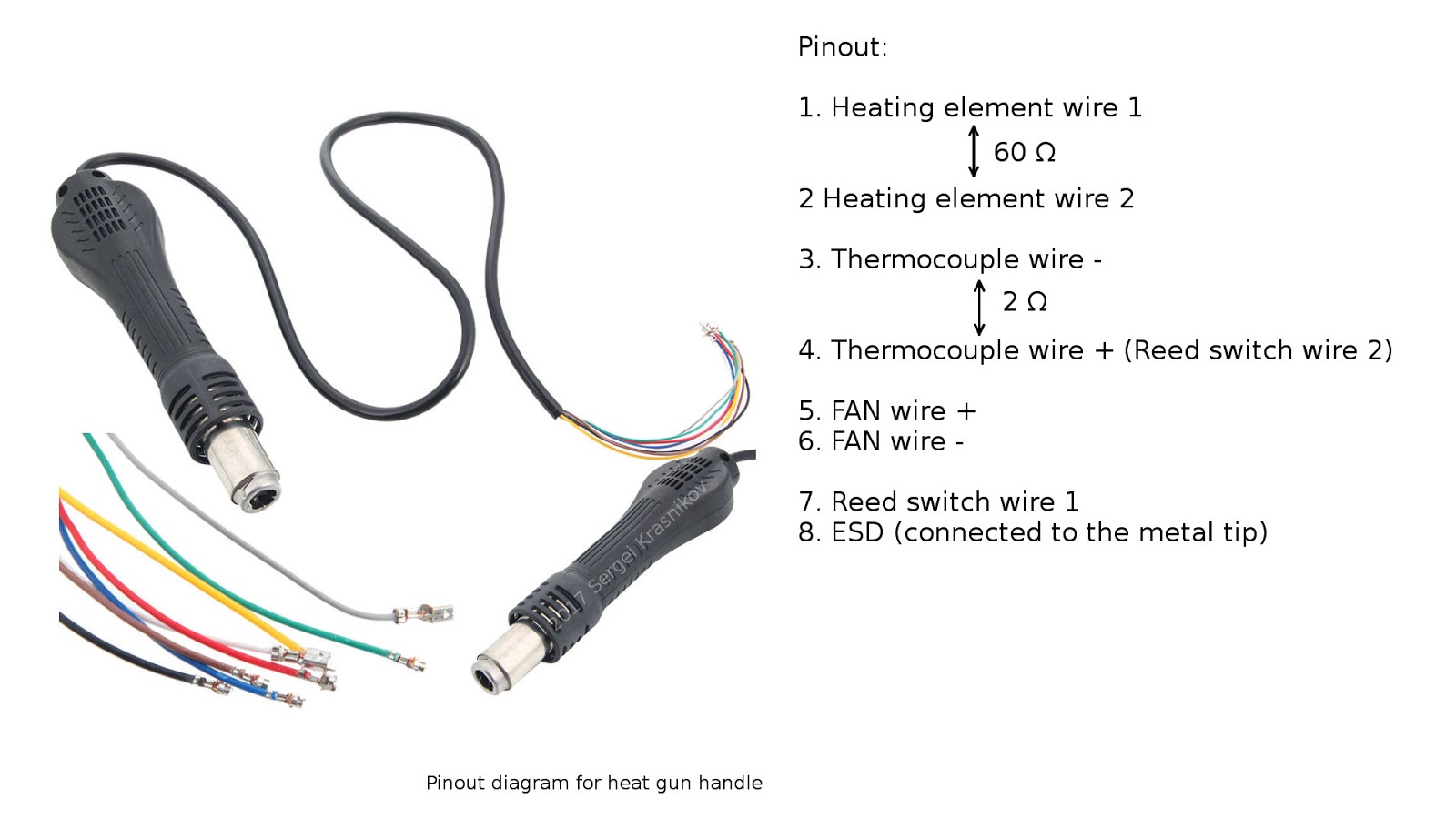

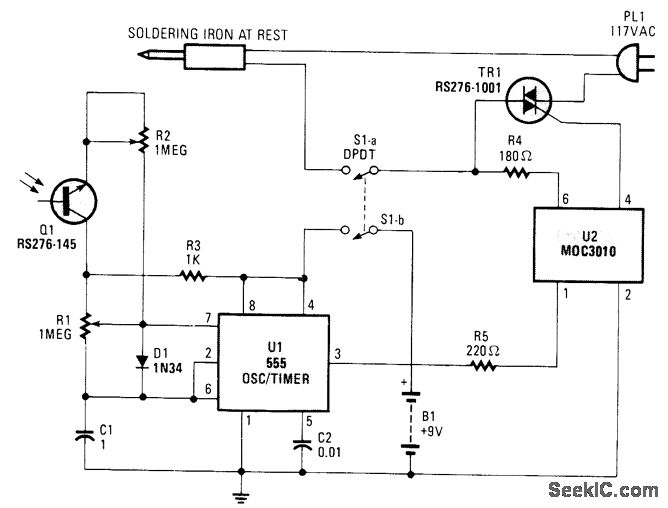

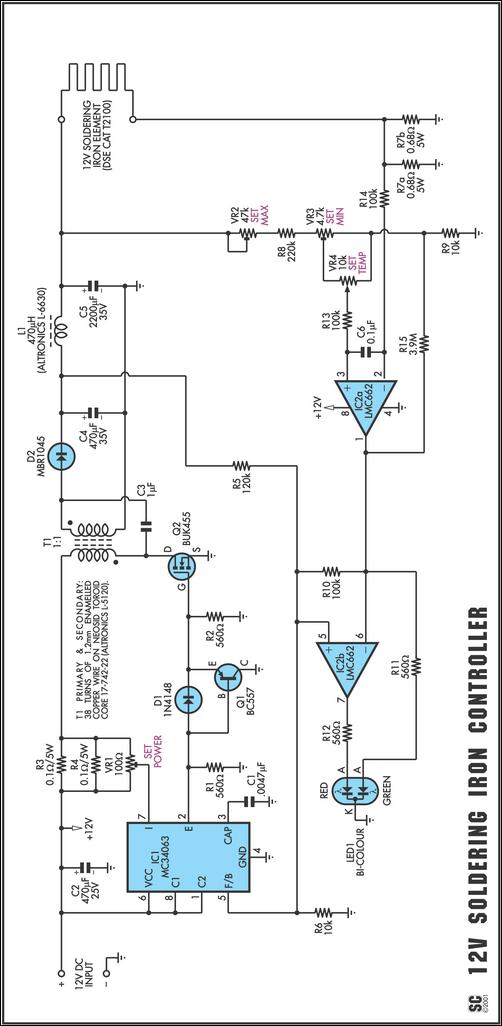

On the 1a soldering station the heating element is connected between pins 1 and 2 on the soldering iron receptacle. Area automatic switch detailed circuit diagram available from the q and a nuts volts magazine controlled 24v control heat to 450 degrees projects circuits usb teardown reverse. This helps prevent seizure and reduction of the tip temperature. Power to the heating element is turned off, the buzzer will sound three times. Disconnecting the soldering iron cord. Soldering station circuit schematic diagram.

Schematic diagram of the host panel tempic down air up rework temp c 2in set icmh solder down air set solder 12 10 11 hot air gun display status.

So refer to the wiring diagram in the photo and follow the path of the wire to find the respective pins. When normally functioning, the resistance of a heating element should read between 19ohms and 23ohms. If rated voltage is 220v, then it should be y connection (star connection). Anything beyond that means that your heating element is not functional. Circuit diagram of soldering iron wiring diagram line wiring diagram. The heating elopement wiring has a cylindrical design and is an excellent choice for prolonged use.

Source: whatmindsaid.blogspot.com

Source: whatmindsaid.blogspot.com

Disconnecting the soldering iron cord. Fan on it works but doesnt heat. Disconnecting the soldering iron cord. First, i cut the power cord in half using a pair of wire cutters. Wiring diagram line we are make source the schematics, wiring diagrams and technical photos.

Source: e1ectro.blogspot.com

Source: e1ectro.blogspot.com

Although either of the two following calibration methods can be used, calibration with a tip thermometer is more accurate. This effectively reconnected one of the cut wires. When the iron reaches a preset temperature, as set by vr4, the output of ic2a goes high. The size of heating torch and the composition of the. Set the temperature to 400 °c (750 f).

Source: whatmindsaid.blogspot.com

Source: whatmindsaid.blogspot.com

Failure to do so may result in damage to the circuit board. Failure to comply with a warning may result in serious injury to the user or others. Pins 1 and 2 correspond to ceramic heater wires. Heating elements are usually integrated into the soldering iron works by converting electrical energy into heat in a process known as joule or resistive heating. Soldering may be applied by using a soldering iron, by flame heating, resistance heating, induction heating, hot plate heating or oven heating, by dipping or by means of a spray gun.the first three methods are used primarily for manual soldering.

Source: evan-mclaughlin.blogspot.com

Source: evan-mclaughlin.blogspot.com

Calibration is required whenever the soldering iron, or its heating element or tip have been replaced. Arduino controls heating element tutorial. First, i cut the power cord in half using a pair of wire cutters. Failure to comply with a caution may cause damage to the product. Circuit diagram of soldering iron wiring diagram line wiring diagram.

Source: eevblog.com

Source: eevblog.com

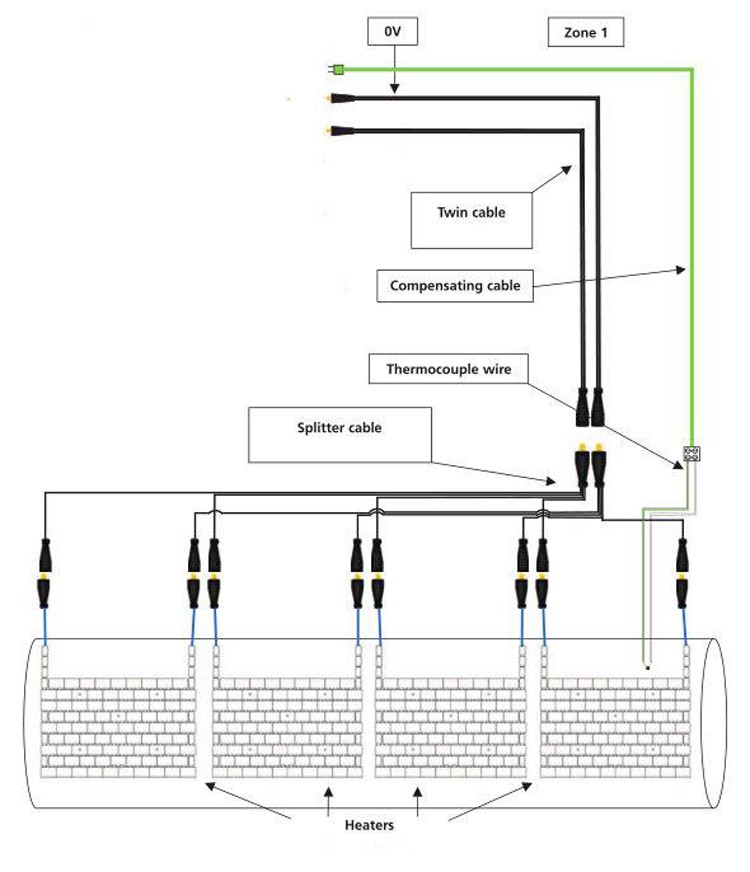

Heating elements are usually integrated into the soldering iron works by converting electrical energy into heat in a process known as joule or resistive heating. Controlling the heating mecha wiring methods of electric water heater element dave s place electrical diagnosis for solved draw a schematic diagram connect 3 phase hot how do elements work explain sic 2 thermocouple bartscher 200240 bain marie 1 1gn petersen waterers livestock sheep horse oven battery. Pay attention to the rated voltage of the heater before operation. On the 1a soldering station the heating element is connected between pins 1 and 2 on the soldering iron receptacle. This soldering iron has a mica tube heating element and adapts well for this project.

Source: wiringschema101.blogspot.com

Source: wiringschema101.blogspot.com

Wiring the heating elements you already have. (this user manual is based on ts100 dfu:3.45, app ver:2.18) warning: When the iron reaches a preset temperature, as set by vr4, the output of ic2a goes high. Failure to comply with a warning may result in serious injury to the user or others. Must heat the tip sufficiently to melt the solder.

Source: e1ectro.blogspot.com

Source: e1ectro.blogspot.com

Soldering iron schematic diagram wiring diagram line wiring diagram. When the iron reaches a preset temperature, as set by vr4, the output of ic2a goes high. (2) replace a new one and solders to pc board properly. Fan on it works but doesnt heat. The heating elopement wiring has a cylindrical design and is an excellent choice for prolonged use.

Source: alibaba.com

Source: alibaba.com

Soldering irons incorporate two components inside, that is, a temperature adjustment control and a heating element. Set the temperature to 400 °c (750 f). Pins 1 and 2 correspond to ceramic heater wires. From the solder and flux can form impurities on the tip. Different parts of an electric iron.

Source: zl2pd.com

Source: zl2pd.com

If rated voltage is 220v, then it should be y connection (star connection). Then replace your filament with a new one by attaching your new filament to the wires where you cut the old filament�s terminal.you must use electrical tapes or tapes that were designed to stand on high. Heating elements are usually integrated into the soldering iron works by converting electrical energy into heat in a process known as joule or resistive heating. Calibration is required whenever the soldering iron, or its heating element or tip have been replaced. Although either of the two following calibration methods can be used, calibration with a tip thermometer is more accurate.

The size of heating torch and the composition of the. Although either of the two following calibration methods can be used, calibration with a tip thermometer is more accurate. Nl lm324 hacked by tokeichun use 220v 110 v ac circuitlab saving at89c2051 led display atmega32 avr best 12v induction heater zl2pd saga usb teardown and reverse engineer adafruit. Set the temperature to 400 °c (750 f). Wiring the heating elements you already have.

Source: wiringschema101.blogspot.com

Source: wiringschema101.blogspot.com

Then replace your filament with a new one by attaching your new filament to the wires where you cut the old filament�s terminal.you must use electrical tapes or tapes that were designed to stand on high. From a pin point for precision soldering to a wider tip for larger wires. When using the soldering iron continuously, be sure to loosen the tip and remove all oxides at least once a week. Then i pulled apart the individual wires on each piece. This soldering iron has a mica tube heating element and adapts well for this project.

Source: pinterest.com

Source: pinterest.com

If the heating elements rated voltage is 380v, then heaters should use delta connection. Wiring diagram line we are make source the schematics, wiring diagrams and technical photos. Failure to do so may result in damage to the circuit board. After you have opened your soldering iron, remove the filament by means of a cutter pliers. Then i pulled apart the individual wires on each piece.

![[NX_1375] Weller Soldering Iron Wiring Diagram Schematic [NX_1375] Weller Soldering Iron Wiring Diagram Schematic](https://static-resources.imageservice.cloud/606101/wiring-details-for-the-soldering-station-arduino-electronics.jpg) Source: weasi.basi.favo.monoc.xeira.embo.inst.crove.bletu.benol.mohammedshrine.org

Source: weasi.basi.favo.monoc.xeira.embo.inst.crove.bletu.benol.mohammedshrine.org

- replace the heating element and install it well according to the contrary method. The tip must be appropriate for your. Must heat the tip sufficiently to melt the solder. This output voltage is applied to a resistance bridge in which the heating element of the iron forms one leg. These impurities can result in defective joints or reduce the tip�s heat conductivity.

Source: electronics.stackexchange.com

Source: electronics.stackexchange.com

Wiring the heating elements you already have. Anything beyond that means that your heating element is not functional. Although either of the two following calibration methods can be used, calibration with a tip thermometer is more accurate. The new heating element may now be soldered onto the pcb in the same location as the element that was removed. On the 1a soldering station the heating element is connected between pins 1 and 2 on the soldering iron receptacle.

Source: google.com

Source: google.com

First, i cut the power cord in half using a pair of wire cutters. Heating elements are usually integrated into the soldering iron works by converting electrical energy into heat in a process known as joule or resistive heating. So refer to the wiring diagram in the photo and follow the path of the wire to find the respective pins. Listed model only (2 each ) 3 ec232 handle assembly 13 n/a soldenoid / transducer assembly 4 ds103 collector tube w/gaskets 14 n/a transformer 5 ds204 filter for desoldering head 15 ph120iesd soldering iron stand (not shown) Soldering station circuit schematic diagram.

Source: whatmindsaid.blogspot.com

Source: whatmindsaid.blogspot.com

- replace the heating element and install it well according to the contrary method. The replacement of soldering station heating element 1) cut the power and and wait until the heating element is cool. Listed model only (2 each ) 3 ec232 handle assembly 13 n/a soldenoid / transducer assembly 4 ds103 collector tube w/gaskets 14 n/a transformer 5 ds204 filter for desoldering head 15 ph120iesd soldering iron stand (not shown) When the iron reaches a preset temperature, as set by vr4, the output of ic2a goes high. The heating element connects to pins 1 and 2 of your soldering iron receptacle.

Source: nte-electronicscircuit.blogspot.com

Source: nte-electronicscircuit.blogspot.com

On the 1a soldering station the heating element is connected between pins 1 and 2 on the soldering iron receptacle. Then i pulled apart the individual wires on each piece. When the iron reaches a preset temperature, as set by vr4, the output of ic2a goes high. Pay attention to the rated voltage of the heater before operation. Set the temperature to 400 °c (750 f).

Source: easycircuit012.blogspot.com

Source: easycircuit012.blogspot.com

First, i cut the power cord in half using a pair of wire cutters. Solder one of the two red wires from the heating element to the red wire from the cord on the pcb, and then. From a pin point for precision soldering to a wider tip for larger wires. Failure to comply with a caution may cause damage to the product. Next, i stripped the insulation off of the cut ends.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title soldering iron heating element wiring diagram by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.

Category

Related By Category

- Truck lite wiring diagram Idea

- Single phase motor wiring with contactor diagram information

- Humminbird transducer wiring diagram Idea

- Magic horn wiring diagram Idea

- Two plate stove wiring diagram information

- Kettle lead wiring diagram information

- Hubsan x4 wiring diagram Idea

- Wiring diagram for 8n ford tractor information

- Winch control box wiring diagram Idea

- Zongshen 250 quad wiring diagram information